The proper mesh count will bring a long-lasting positive outcome to the production process of your Screen Printing Machine.

Often, the new entrepreneur or fresher with a screen printing press gets confused about choosing the correct mesh count. Due to this confusion and ignorance, many new and seasonal screen printer birds use similar medium-grade mesh counts for all their jobs.

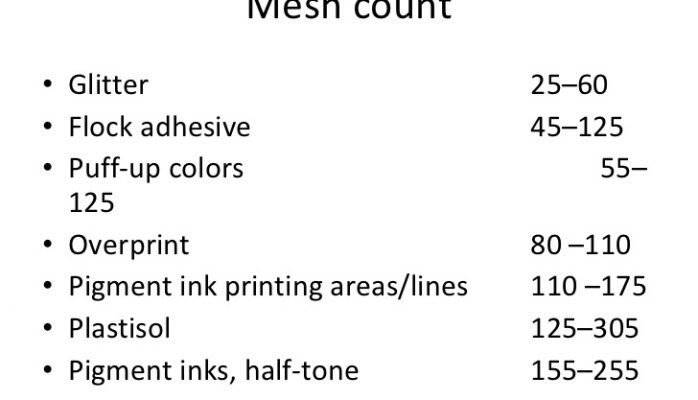

The proper mesh count will make a massive difference in your silk-screen jobs. Here’s a list of the different mesh counts and the plastisol ink(s) that would work per screen printing job.

The proper mesh count will bring a long-lasting positive outcome to the production process of your screen printing machine.

Often, the new entrepreneur or fresher with a screen printing press gets confused about choosing the correct mesh count. Due to this confusion and ignorance, many new and seasonal screen printer birds use similar medium-grade mesh counts for all their jobs.

As a mid-range 160 mesh screen printing entrepreneur, you should learn to precisely determine the result and outcome, or feedback, by using different screen mesh counts for various projects.

This article provides an idea for determining the mesh count for a screen printing machine. You can choose from which point you begin when printing with different mesh counts to achieve various printing outputs.

Fundamentals of Screen Mesh Count:

For your understanding of the screen mesh count, first, you should learn and estimate the details about the mesh count. The mesh count refers to the number of fibers retained within one square inch of the screen.

It means a 160 mesh count screen contains 160 fibers within one square inch of the screen. The screen with a lower mesh count has larger openings that permit more ink to run through, whereas finer details in your printing are achieved through a higher mesh count with less coating ink.

Learn Which Mesh Count to Use for a Screen Printing Machine

Professional knowledge will facilitate you to decide which mesh counts would give preference to use on particular projects; however, some guidelines are described below here with by which you will help to start by using different mesh counts:

- Using a 25 to 40 mesh count screen will yield perfect glitter or glisten inks, as these inks have particles that are unable to pass through the finer mesh.

- Sixty mesh counts allow for a heavy ink to be applied. Block numbers and letters on athletic jerseys are frequently used.

- A mesh count of 80 to 86 is commonly used to produce heat transfers, print heavy underbases, and utilize specialty inks, such as puff ink.

- Screens with mesh counts ranging from 110 to 160 are the most adaptable and frequently used in screen printing machines. Screens on the lower end of the mesh count spectrum produce heavier ink deposits and are ideal for printing under bases or bold colors on dark fabrics. You can print a more detailed image at the higher end of the mesh count spectrum while maintaining a fair ink deposit.

- A mesh count of 180 to 200 is ideal for printing full images in light inks on dark fabrics.

- 230- to 280-mesh count screens will produce comprehensive prints with a softer hand feel. On the other hand, as they permit lighter ink deposits, prints made with these fine screens won’t be as dazzling or bright.

Other factors in choosing a Screen Mesh Count

Keep in mind some other factors while experimenting with different mesh counts in your screen printing equipment.

First, screens of diverse densities will catch different amounts of mixture; a mid-lower mesh counts holding more. When using a lower mesh count screen, you’ll need to provide your screens with more time to allow the mixture to set correctly.

The ink will dry out more rapidly on finer screens while printing with water-based inks. You might want to insert a retarder into your water-based ink to prevent the ink from transferring and your job from becoming stirred.

You decide which screen mesh counts are best for your screen printing machine for which jobs, and you are the final decision-maker for which mesh count you should use.

From first to last experience and testing with different screen densities, you’ll find which screens provide you with the desired outcome when dealing with other types of projects.

Leave a Reply

You must be logged in to post a comment.