In the competitive landscape of small businesses, making the right choices can determine your success. One critical decision is selecting the appropriate printing method for your products.

The screen-printing technique you choose can significantly impact your product quality, production costs, and overall customer satisfaction.

Among the most popular options available are screen printing and sublimation. Each method has its unique advantages and limitations, catering to different needs and types of projects.

Understanding these differences is essential for small business owners looking to create high-quality custom apparel or promotional items.

In this article, we will explore the key aspects of screen print vs sublimation, helping you determine which method best suits your business requirements.

Understanding Screen Printing

Screen printing, also known as silk screening, is a technique that involves transferring a stenciled design onto a surface using a mesh screen, ink, and a squeegee.

The process begins with creating a stencil on the mesh screen, which blocks certain areas to allow ink to pass through.

This method is highly regarded for its durability and longevity, producing vibrant prints that can withstand repeated washing and wear. However, screen printing does have its drawbacks. The setup time and costs can be significant, especially for small runs, as each color requires a separate screen.

This can make it less cost-effective for small orders compared to other printing methods.

Ultimately, while screen printing offers excellent quality and durability, it may not be the best choice for every project, particularly those with limited budgets or smaller quantities.

Understanding Sublimation Printing

Sublimation printing, also known as dye sublimation, is a unique printing method that transfers dye onto materials using heat and pressure. The process begins by printing your design onto special sublimation paper with sublimation inks.

Once printed, the paper is placed on a substrate—typically polyester or a polymer-coated item—and subjected to high temperatures and pressure using a heat press.

This causes the ink to turn into gas, allowing it to bond permanently with the fibers of the material.

The result is vibrant, full-color prints that are highly resistant to fading and cracking. Sublimation is limited to polyester and polymer-coated substrates, which restricts its versatility compared to other printing methods.

While it excels in producing detailed and colorful designs, businesses must ensure they have the right materials to achieve the best results.

Key Differences between Screen Print vs Sublimation

Print Quality and Durability

When comparing print quality and durability between screen printing and sublimation, both methods have distinct characteristics that cater to different needs.

Screen Printing is known for producing excellent print quality with vibrant and sharp colors. The thick layers of ink create bold visuals that stand out, making it ideal for designs that require high visibility.

One downside is that the ink can crack or peel over time, especially if the printed items are subjected to frequent washing or wear.

Despite this, screen printing can be applied to a wide range of materials, including cotton, polyester blends, and more, allowing for greater versatility in product offerings.

On the other hand, Sublimation Printing delivers durable and resistant prints that are less likely to crack or peel.

This is because the dye becomes part of the fabric rather than sitting on top of it. However, sublimation is primarily suitable for polyester-based materials or polymer-coated substrates.

While sublimation prints may not achieve the same level of vibrancy as screen prints on certain fabrics, they excel in producing detailed designs with smooth gradients and color transitions.

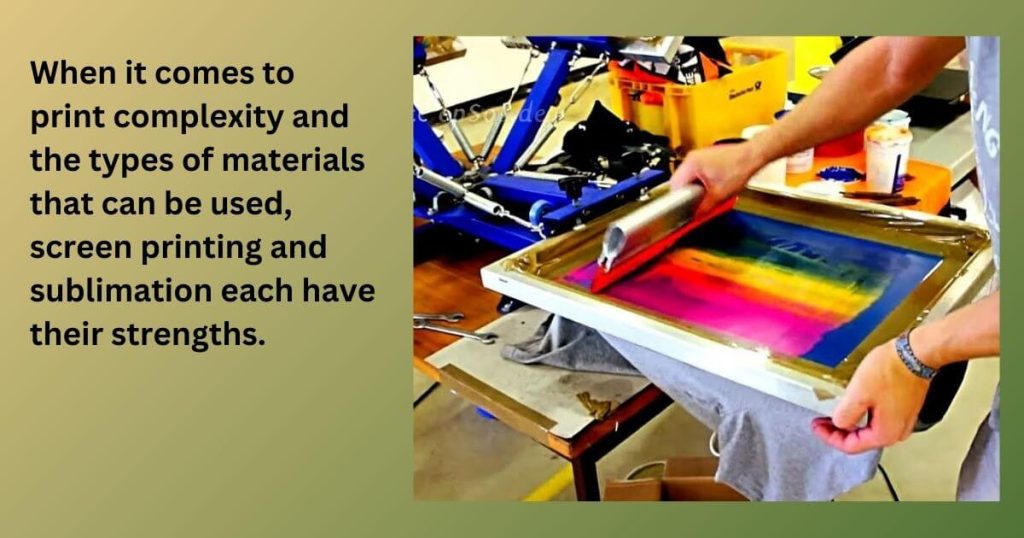

Print Complexity and Materials : Screen Print vs Sublimation

When it comes to print complexity and the types of materials that can be used, screen printing and sublimation each have their strengths.

Screen Printing is particularly well-suited for simple designs that utilize one or a few colors.

The process involves creating separate screens for each color, which can make it less efficient for intricate designs with multiple hues.

When it comes to bold graphics or logos, screen printing excels, producing sharp lines and vibrant colors.

Additionally, screen printing offers versatility in terms of materials; it can be applied to a wide range of substrates, including natural fibers like cotton, blends, and even some synthetic materials.

In contrast, Sublimation Printing shines when handling complex designs that incorporate multiple colors and intricate details.

This method allows for full-color prints with smooth gradients and photographic quality, making it ideal for custom apparel and promotional items that require detailed artwork.

However, sublimation is limited to synthetic materials, primarily polyester or polymer-coated substrates. This restriction means that while sublimation can produce stunning visuals on the right materials, it may not be suitable for all fabric types.

Cost and Efficiency: Screen Print vs Sublimation

Cost Efficiency and Equipment Setup

When evaluating cost efficiency and equipment setup for screen printing and sublimation, it’s important to consider both initial investments and long-term costs.

Screen Printing tends to be more cost-effective for bulk orders. As production volume increases, the cost per unit decreases significantly due to the ability to reuse screens for multiple prints.

However, this method requires a substantial initial investment in equipment, including screens, squeegees, and a printing press. The setup process can be time-consuming, especially for multi-color designs, which adds to the overall costs.

On the other hand, Sublimation Printing also involves a considerable initial setup cost for the printer and heat press. However, it can be more cost-effective for small orders since there are no screens to create or maintain.

The equipment setup for sublimation is generally less complex and requires fewer materials upfront compared to screen printing. This makes sublimation an attractive option for businesses that focus on custom designs or lower-volume production runs.

In summary, if your business primarily handles large orders, screen printing may offer better long-term savings. However, if you focus on smaller, custom jobs, sublimation could provide a more economical solution with lower initial setup costs.

Setup Time and Production

When comparing setup time and production efficiency between screen printing and sublimation, each method has distinct characteristics that can impact workflow.

Screen Printing typically requires a longer setup time, especially for complex designs that involve multiple colors. Each color necessitates the creation of a separate screen, which can be time-consuming and labor-intensive.

Once the setup is complete, screen printing is capable of producing large quantities quickly. This makes it highly efficient for bulk orders, as the process allows for rapid printing once the initial preparations are done.

In contrast, Sublimation Printing has a relatively shorter setup time. The process involves fewer steps, as it primarily requires preparing the design and setting up the heat press.

However, sublimation may require individual attention for each product, particularly if different designs or sizes are involved. This can slow down production when dealing with multiple custom items.

While sublimation is efficient for smaller runs or one-off designs, it may not match the high-volume output speed of screen print.

Choosing the Right Method

Consider Your Business Needs and Design Requirements

When deciding between screen printing and sublimation, it’s crucial to align your choice with your business needs and design requirements.

Choose Screen Printing if your focus is on bulk production of simple, bold designs across various fabric types. This method is particularly effective for larger orders, allowing you to achieve vibrant colors and durable prints at a lower cost per unit.

If you frequently produce items like t-shirts, hoodies, or promotional materials that require solid colors and high visibility, screen printing is the ideal choice.

Choose Sublimation Printing when your projects involve full-color designs, intricate graphics, or photographic images on synthetic fabrics like polyester.

This method allows for exceptional detail and smooth gradients, making it perfect for custom apparel, sportswear, and personalized products. Sublimation is especially beneficial for smaller runs or unique items where customization is key.

As you make your decision, consider the cost implications, production efficiency, and material compatibility of each method. By carefully evaluating these factors, you can select the printing technique that best meets your business goals and enhances your product offerings.

Conclusion

In this article, we explored the key differences between screen printing and sublimation, two popular methods for creating custom prints. Screen printing is ideal for bulk production of simple, bold designs on a variety of fabrics, offering durability and cost-effectiveness for larger orders.

In contrast, sublimation excels in producing vibrant, full-color prints on synthetic materials like polyester, making it perfect for intricate designs and smaller runs.

As you consider which method is best for your small business, it’s important to assess your specific needs, target market, and product offerings.

Think about the types of designs you want to create, the materials you’ll be using, and your production volume. By carefully evaluating these factors, you can make an informed decision that aligns with your business goals and enhances your product line.

Whether you choose screen printing or sublimation, each method has unique advantages that can help you succeed in the competitive landscape of custom printing.

Leave a Reply

You must be logged in to post a comment.