Screen printing excels in durability and cost-effectiveness for large quantities. Digital printing offers precision and versatility with no minimum volume.

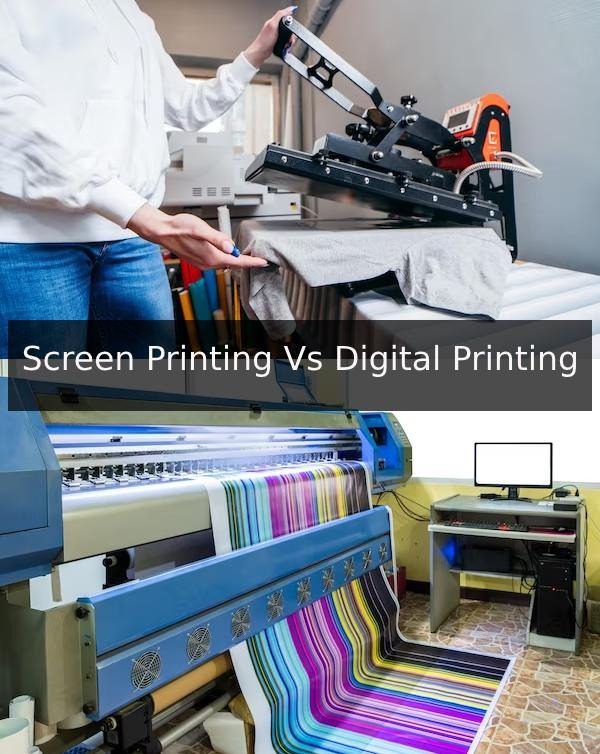

Choosing between screen printing and digital printing for your custom apparel or projects requires understanding their advantages and limitations. Deciding on a printing method is a critical step that affects the quality, cost, and production time of your finished products.

Screen printing, a traditional technique, is renowned for its vibrant, long-lasting prints and is cost-efficient at high volumes. In contrast, digital printing stands out for its detailed print quality and the ability to produce small batches or one-offs economically. As businesses and individuals weigh their options, considering both the pros and cons of each method ensures informed decision-making that aligns with project needs and budget.

Introduction to Printing Techniques

Embarking on a journey through the realm of textile embellishment, navigating the different shores of printing technologies is essential. Among these, screen printing and digital printing emerge as the titanic duo, each with merits and limitations. Today, we’ll delve into the intricacies of both through an educational and illuminating lens, paving the way for a better understanding of the methods that transform plain fabrics into vibrant tapestries of colors and patterns.

Definition of Screen Printing

Screen printing, commonly known as silkscreen or serigraphy, involves creating a stencil (called a ‘screen’) and then applying layers of ink on the printing surface. Each color is added separately using a distinct stencil. All the stencils are combined to achieve the final look. The technique is notable for its versatility over a wide array of materials and its ability to produce vibrant colors, which are often more durable than those produced by digital printing.

Definition of Digital Printing

In contrast, digital printing is a much newer process that involves your design being processed by a computer and then printed directly onto the surface of your product. Digital printing is not limited by the number of colors you can use, so it’s a good choice for designs that require full-color prints or meticulous detail.

Brief History of Both Printing Methods

From ancient Chinese stencils to the latest inkjet technology, the evolution of screen and digital printing is fascinating. Screen printing is deeply embedded in history, dating back to China’s Song Dynasty (960–1279 AD). It traversed the globe, flourishing under different names and techniques, universally adapting and evolving. On the flip side, digital printing debuted in the early 1990s. It brought the dawn of direct-to-garment (DTG) printing, a technique that has revolutionized the industry by permitting intricate, detailed work with a quick turnaround.

Understanding Screen Printing

Screen printing, a technique with a storied legacy, remains a favorite for artists and businesses alike, revered for its versatility and vibrant finishes. The traditional printing process involves making a stencil and applying layers of ink on the printing surface, one color at a time. This method produces a robust and long-lasting design that often has a unique, handcrafted feel that modern techniques cannot recreate.

The Screen Printing Process Explained

At its core, screen printing involves a simple but meticulous process. Here’s a quick breakdown:

- Creating the Design: The desired image is printed onto a transparent acetate film, which will be used to develop the stencil.

- Preparing the Screen: A mesh screen is coated with light-reactive emulsion, then the acetate film is placed on top, exposing it to bright light. The uncovered areas will harden while the design stays liquid.

- Washing Off the Stencil: The unhardened emulsion is washed away, leaving the stencil behind.

- Printing: The screen is positioned over the printing surface, and ink is pushed through the mesh onto the material below.

- Curing: The print is dried, or ‘cured,’ to ensure durability and longevity.

Materials and Tools Used In Screen Printing

Screen printing calls for a unique set of materials and tools:

- Screens: Mesh screens made of synthetic polymers like nylon,

- Frame: A support frame, generally aluminum or wood,

- Inks: Specialized inks that are formulated for screen printing,

- Squeegees: Rubber-bladed tools used to push the ink through the mesh,

- Emulsions: Photosensitive coatings that create the stencil.

Suitable Applications for Screen Printing

Screen printing shines in a variety of applications:

- Textiles: T-shirts, hats, and tote bags,

- Promotional Items: Pens, USB drives, and coasters,

- Signage and Displays: Posters, banners, and retail signs,

- Product Labels: For bottles or packaging,

- Electronics: Circuit boards and control panels.

Pros of Screen Printing

The advantages of screen printing are numerous:

- Color Vibrancy: Inks lay down thicker than digital, resulting in deeper coloration,

- Durability: Prints withstand more stress, washing, and use,

- Versatility: Works on a multitude of substrates, including uneven surfaces,

- Cost-Effective for Large Runs: The more units printed, the cost per unit drops significantly,

- Eco-Friendly Options: Availability of water-based and eco-conscious inks.

Cons of Screen Printing

While esteemed for many reasons, screen printing also has its limitations:

- Setup Time: Preparing screens and stencils requires substantial setup,

- Costly for Small Batches: Initial setup fees can be high, making small orders less economical,

- Complexity with Multiple Colors: Each color requires a separate screen, increasing time and cost with multicolored designs,

- Resolution Limitations: Fine details may not be as sharp as digital printing,

- Cleanup: The process can be messy and requires thorough cleanup.

Delving Into Digital Printing

With the striking advancements in printing technology, digital printing has emerged as a focal point of interest amongst artists and businesses alike. Delving into Digital Printing reveals an expanse of possibilities that blend speed, precision, and versatility, revolutionizing how we bring designs to life. Let’s unfold the layers of the digital printing process and discover its true essence, including the materials, uses, and associated pros and cons of this modern-day printing technique.

The Digital Printing Process Uncovered

Digital printing is a direct-to-media print method where digital-based images are printed directly onto various media substrates. Unlike traditional screen printing, which requires screens to transfer the design, digital printing uses complex software that interprets your artwork and prints it directly onto your material of choice. It typically involves preparing your digital file, ensuring its quality and resolution, choosing the correct substrate, and then allowing the digital printer to recreate your design precisely.

Materials and Tools Utilized In Digital Printing

- Digital Printers: High-tech printers capable of producing high-resolution images.

- Inks: Usually, solvent, UV-curable, dye sublimation, or aqueous-based.

- Substrates: A broad range, including paper, canvas, fabric, plastic, metal, and more.

- Software: Programs like Adobe Illustrator or Photoshop to prepare and process designs.

- Color Profiling: Tools for color accuracy and consistency across prints.

Ideal Uses for Digital Printing

Digital printing stands out when working on short-run jobs, personalized prints, or when time constraints are tight. Here are some prime examples:

- Custom apparel or merchandise with vibrant, multicolored designs.

- Print-on-demand services, where each item can be unique.

- Marketing materials such as flyers, brochures, and business cards.

- Large format printing, including posters and signage.

- Photographic quality prints where detail and color depth are crucial.

Advantages of Digital Printing

Think about harnessing the power of precision and flexibility with digital printing. The process has several noteworthy advantages:

|

Advantage |

Description |

|

Efficiency |

Speedier turnaround times with no need for pre-press stages. |

|

Versatility |

Ability to print on various materials and customize each print. |

|

Quality |

High-resolution images with excellent color accuracy. |

|

Economical |

Cost-effective for small runs due to minimal setup costs. |

| Eco-Friendly |

Less waste and fewer chemicals compared to traditional methods. |

Advantage Description

| Disadvantage | Description |

| Cost per Unit | Higher unit cost for bulk orders compared to screen printing. |

| Lifespan | Prints may not have the same durability as those from screen printing. |

| Material Constraints | Some limitations on thickness and type of materials that can be used. |

| Color Matching | Digital prints may exhibit variations in color when compared to Pantone swatches. |

| Size Restrictions | Potential size limitations depending on the digital printer’s capacity. |

Efficiency Speedier turnaround times with no need for pre-press stages.

Versatility Ability to print on various materials and customize each print.

Quality High-resolution images with excellent color accuracy.

Economical Cost-effective for small runs due to minimal setup costs.

Eco-Friendly Less waste and fewer chemicals compared to traditional methods.

Disadvantages of Digital Printing

Despite its many benefits, digital printing does come with limitations that one must consider:

Disadvantage Description

Cost per Unit Higher unit cost for bulk orders compared to screen printing.

Lifespan Prints may not have the same durability as those from screen printing.

Material Constraints Some limitations on thickness and type of materials that can be used.

Color Matching Digital prints may exhibit variations in color when compared to Pantone swatches.

Size Restrictions Potential size limitations depending on the digital printer’s capacity.

Comparative Analysis

When customizing fabrics and materials, screen printing and digital printing stand out as the prime methods. Both have carved niches with distinct advantages and limitations. This comparative analysis will evaluate various aspects, including cost, quality, durability, efficiency, speed, environmental impact, and customization possibilities. Businesses and individuals can make informed choices about which printing method aligns with their project goals by understanding the nuances of each technique.

Cost Comparison between Screen Printing and Digital Printing

The cost framework of printing methods often steers decision-making. Screen printing is renowned for its economical scalability in large orders. The unit cost decreases as volume increases, making it an ideal choice for substantial batch sizes. However, the initial setup costs for screen printing can be higher due to the creation of screens, one for each color in the design.

In contrast, digital printing shines with low-volume orders. It requires no setup costs and offers a fixed cost per unit, regardless of the quantity. But, as quantities rise, the cost benefits of digital printing start to diminish when compared to screen printing.

Quality and Durability: A Side-by-side View

• Screen Printing: It delivers vibrant colors that penetrate deeply into the material, resulting in superior color fastness. The end product can sustain numerous washes without fading.

• Digital Printing: It provides a high-resolution print with detailed image quality, ideal for intricate designs. However, while improvements have been made, the print may not be as durable as screen prints.

Efficiency and Speed: What Sets Them Apart

Aspect Screen Printing Digital Printing

Setup Time Longer due to screen preparation. Minimal, direct from digital files.

Turnaround Faster for large batches post-setup. Quick for small to medium orders.

Environmental Impact: Assessing the Eco-friendly Option

Screening the ecological footprint of these printing methods is imperative. Screen printing often uses more water and plastisol inks that may contain harmful compounds. Nonetheless, eco-conscious alternatives like water-based inks are available.

Digital printing is labeled as a more environmentally friendly alternative. It reduces ink waste and energy usage, especially with direct-to-garment techniques that use water-based inks.

Customization and Flexibility: Choosing the Right Method for Your Project

The final portrayal of your creative concepts hinges on the adaptability of the chosen printing process. Screen printing offers a high level of customization for specialized inks and materials but is less adaptable to intricate multicolored images, especially on small scales.

Digital printing thrives in personalization and variable data capabilities, excelling with intricate, high-resolution graphics and smaller quantities. It is the go-to for projects requiring detailed imagery or designs that use various colors.

Making Your Choice: Screen Printing or Digital Printing

Two prominent methods stand out regarding breathing life into your designs through printing: screen printing and digital printing. Each technique comes with its own set of advantages and considerations. Navigating the decision on which one to use could be overwhelming, especially with the nuances in quality, cost, and production. This section sheds light on critical variables to weigh to make an informed choice between screen printing and digital printing.

Factors to Consider When Choosing A Printing Method

The selection between screen printing and digital printing hinges on several crucial factors. These include the material of the substrate, desired print durability, color accuracy, and environmental impact. Budget limitations and turnaround time also dictate the choice. To facilitate the decision-making process, it’s essential to align these factors with the demands of your project.

Impact of Volume on Printing Selection

• Screen Printing: Ideal for large batches due to its cost-effectiveness at higher volumes.

• Digital Printing: More suited for smaller quantities as it offers a lower setup cost and faster production for limited runs.

Volume is a decisive element as the cost-per-unit drops significantly with screen printing for bulk orders, while digital printing remains constant regardless of the number of prints.

The Role of Design Complexity in Method Selection

Feature Screen Printing Digital Printing

Color matching Offers precise spot colors Limited by the four-color (CMYK) process

Gradient and detail Better for bold and solid block colors Capable of printing intricate details and smooth gradients

Texture effects Possibility of creating unique tactile finishes Generally provides a flat print surface

It’s critical to assess the complexity and color requirements of the design. While screen printing excels at vibrant and specialized inks, digital printing is the go-to for detailed imagery and photo-realistic designs.

Final Thoughts and Recommendations

Evaluate your priorities when deciding between screen and digital printing. If sustainability is a crucial concern, consider each method’s waste and energy consumption. For fast production times, digital printing stands out. For durability and specialized textiles, screen printing may be the better fit. Ultimately, the choice depends on aligning your project’s needs with the strengths of each printing technique.

FAQ of Screen Printing Vs. Digital Printing: Pros and Cons Unveiled

Is Digital Printing Better Than Screen Printing?

Digital printing offers faster turnaround and detailed designs, ideal for low-volume orders. Screen printing provides cost benefits for large runs and offers vibrant color saturation. The choice depends on order size and design complexity.

What Are the 4 Disadvantages Of Screen printing?

Screen printing can be less cost-effective for small batches. It requires a lengthy setup process. The technique offers limited color shades on dark fabrics. Finally, screen printing entails a high labor intensity, particularly for intricate designs.

What Are The 5 Disadvantages Of Digital Printing?

Digital printing has limited size options and offers lower quality for large-volume jobs. It’s less cost-effective for bulk orders and has a lesser material selection. Color matching can be inconsistent, making it challenging for brand precision.

How Is Digital Technology More Advantageous Than Silkscreen Printing?

Digital technology offers greater precision and versatility in printing, with faster turnaround times and lower short-run costs than silkscreen methods.

Conclusion

Deciding between screen and digital printing depends on your project’s specifics. Screen printing excels in durability and cost-effectiveness for large batches, whereas digital printing stands out with its precision and flexibility for smaller runs. Evaluate your needs, looking at quantity, quality, and costs to make an informed choice that suits your printing requirements perfectly.

Choose wisely and watch your designs come to life!

Leave a Reply

You must be logged in to post a comment.