Do you want to know how to use a Heat Press Machine?

Get into this article and find your learning points.

In the headline of this article, “How to use a heat press machine?”, some readers may take it for granted if they are familiar with heat presses. However, those who have yet to gain some knowledge about heat-pressing will also achieve amazing results.

Because the heat press machine is another blessing of science, it still gets less popularity. Does that mean most people are unaware of heat transfer machines?

Isn’t that?

From now on, you will have no more zero knowledge about a heat press machine, as I am starting to describe it from the very basics to the most advanced features.

When you begin, you will find all the necessary information to get started with this powerful gear. And from how to start using it to how to use it effectively.

8 Easy Steps to Use A Heat Press Machine – screenprintingmachine.net

8 Easy Steps to Use A Heat Press Machine – screenprintingmachine.net

What is a heat press machine?

A heat press machine, you can also call it a heat production machine, because it creates heat when it is connected to a power supply.

Are you familiar with word screen printing?

The heat press is the digital equivalent of the screenprint machine, and the results differ accordingly.

In the past, screen printing was the only way to imprint colors and art on the surface of a fabric. It helped us eliminate the high cost of making custom clothes.

Yes, I am talking about t-shirts! The T-shirt business is the fastest-growing industry among small entrepreneurs’ startups.

Now, think about some uses of t-shirt printing.

Check out the top 10 best t-shirt printing equipment reviews.

1. Beginner’s Guide to Using a Heat Press

It is excellent for shirt business visionaries because, in addition to the fact that the heat press machine is easy to use and affordable, printing is also easy and affordable. It also makes custom shirt printing conceivable. With screen printing, customers must arrange in large quantities, or, in all likelihood, it would be too costly per piece.

Be that as it may, with a heat press machine or shirt press, it’s still affordable regardless of whether they request one or 1,000. There’s no big surprise that the shirt heat press is a favorite of many businesspeople. Consider using a heat press machine if you just got one.

Indeed, Here Is An Essential Guide: How To Use The Heat Press Machine for T-Shirts, Sweatshirts, Hats, Mugs, and More.

Utilizing the Machine

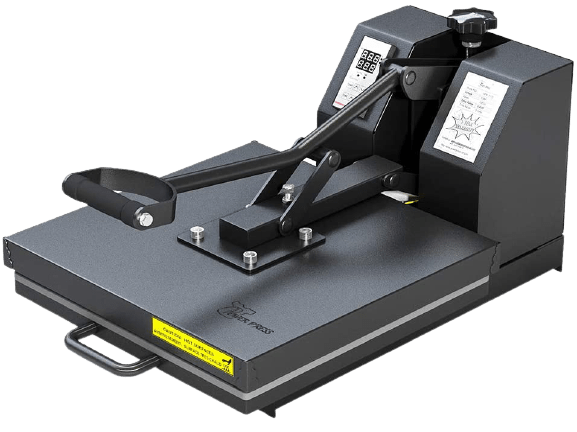

As we know, not all heat press machines are created equal. That’s why it’s usual or unusual to ask how to use a heat press machine.

Those machines are functional (fundamental) and suitable for short positions and home use. They’re substantially more affordable and could be significant, assuming you’re starting and would like to save a couple of hundred bucks.

Depending on the type of printing you plan to do with your shirt press, you want to select a suitable heat press machine. The professional heat press machine is ready for mass requests.

They have a much larger platen (metal board) for a broader working area, catering to curiously large garments. The professional shirt press is also finished with more sophisticated time, temperature, and pressure settings. It is ideal for shirt business visionaries planning to fulfill orders in large quantities in the future.

Whether you’re utilizing the basics or the genius, heat press machines are operated the same way.

Here’s How to Use a Heat Press Machine: Steps to Get Started?

Switch on the power by flipping the on/off switch.

-

- Turn the thermostat handle to one side until you see the red heating light.

- Move the handle back to one side when the thermometer indicates the ideal temperature for your transfer, and continue until the heating light switches off. The heating light will continue to turn on and off to regulate your perfect temperature.

- Assuming your machine has a digital clock, press it to start the clock, and when you hear the alarm, press stop to reset

- Lift the handle to open the press

- Lay the shirt and lay the Transfer Paper onto the shirt, facing down

- Cut the handle down. The handle ought to be securely immovable.

- Set the clock based on the directions on your Transfer Paper

- Lift the handle to open the press

- Strip the Transfer Paper from your shirt

- It allows at least 24 hours for the print to “lock” before washing the shirts.

However, the most crucial differentiation is between home presses and professional ones. The previous one is (mainly) designed for private use. However, you can use it for a business in its nascent stages. Assuming you already handle mass requests or plan to scale to mass creation, then a professional press is better. It offers more pressure and temperature stability settings and stays with the larger plate.

2. Make Sure to choose the Right Material for the heat transfer machine

Unfortunately, you can’t simply use any fabric for the pressing. Some are sensitive to heat, and high temperatures would cause them to dissolve. Avoid thin and fabricated materials; print on cotton, lycra, nylon, polyester, and spandex.

These materials are sufficiently sturdy to withstand heat pressing, while you should consult the label for other uses.

It’s wise to pre-wash your garment, especially assuming it’s new. A few kinks could appear after that first wash, affecting the plan. If you do this before pressing, you will want to avoid such issues.

3. Finding the Accuracy in Making a Design

It is the tomfoolery part of the interaction! Essentially, any image that you can print and also press onto a garment. Assuming you want your business to take off, you want something original to take individuals’ advantage. It would be ideal if you honed your abilities in software like Adobe Illustrator or CorelDRAW. That way, you’ll have the option to join an intelligent thought with a great visual representation.

4. Getting the proper transfer paper to Print Your Design

An essential part of the heat-pressing interaction is the transfer paper. It is a sheet with added wax and shade that your plan is (initially) imprinted on. You can place it over your garment in the press. There are various types of transfers, depending on the type of printer and the color of your material. Here are the most widely recognized ones.

Inkjet transfers

Get the appropriate paper if you have an inkjet printer. Something important to note is that inkjet printers don’t print white. Whatever part of your plan is white will be shown as the shade of the garment when heat-pressed. You can work around this by choosing a grayish shade (which can be printed or used with a white garment for pushing).

Laser printer transfers

There are different paper types for other printers; they don’t work interchangeably, so be sure to select the correct one. Additionally, laser printer paper is often considered to yield poorer outcomes than inkjet paper.

Sublimation transfers

It works with sublimation printers and special ink, a more costly choice. The ink here can turn into a gaseous state that penetrates the fabric, permanently damaging it. It just works with polyester materials, however.

Readymade transfers

You can obtain pre-printed images for the heat press without having to print them yourself. Use your heat press to attach woven plans with heat-touchy adhesives on the back.

When working with transfer paper, it is essential to be aware of several key considerations. A basic one is that you print on the right side. It appears glaringly evident. However, misunderstanding is easy.

5. Prepare The Heat Press

Regardless of the heat press machine you’re using, it’s easy to learn how to operate it. You can set your ideal temperature and pressure with any heat press machine, and there’s also a clock. The press ought to be open while it’s being prepared.

Whenever you turn your heat press on, set the temperature. You turn the thermostat handle clockwise (or utilize the arrow buttons on certain presses) until you reach your ideal heat setting. It will activate the heating light. You’ll realize it has reached your perfect temperature when the light is off. You can turn the handle back at this point, but the light will continue to glow intermittently to maintain the heat.

There is no fixed temperature that you use for all pressing. The packaging of your transfer paper will indicate how to set it up. It will usually be around 350-375°F; worry if it appears high – it should be for the plan to stick accurately. You can always track down an old shirt to test the press.

Then, set the pressure. Turn the pressure handle until you’ve reached the desired setting. Thicker materials usually require more pressure, while thinner ones do not.

It will help you assume that your aim is for medium to high pressure in all cases. However, trying until you’ve observed the level that gives the best outcomes is ideal. A lower pressure setting makes securing the handle on certain presses more challenging.

6. Place Your Garment in The Press

The material you use is straightened when it is placed inside the press. Here, any folds will result in a poor print. To eliminate creases, you can use the press to preheat the garment for 5 to 10 seconds.

Extending the shirt when you place it in the press is also great. The print will contract when you’re done, making it doubtful to crack later. So, ensure that the side of the garment you want to print is facing up. You must align the shirt tag with the back of the press. It will assist with placing the print accurately. A few presses also project a laser framework onto your garment, making it easier to align your plan.

While weaving plans, place your printed transfer face down on the garment and position the adhesive side down. You can place a piece of light cotton fabric on top of your transfer as insurance, although it is not necessary if your press has a protective silicone pad.

7. Transfer the Design

You can cut the handle once the garment and the print are (accurately) placed into the press. It would be ideal for locking, so you don’t have to physically press the top. Set the clock according to your transfer paper guidelines, typically between 10 seconds and one minute.

When the time has passed, open the press and take out the shirt. Strip off the transfer paper while it’s still hot. Ideally, you’ll see your plan effectively transferred onto your garment.

You can repeat the interaction for new shirts, assuming you’re making more of them. Place the cardboard inside it first if you want to add a print to the opposite side of the shirt you’ve already imprinted. Use less pressure to avoid reheating the principal plan.

8. Care For Your Print

It will help you leave your shirt to rest for at least 24 hours before washing it. It allows the print to set in. Turn it inside out when you pass it out, so there isn’t any friction. Please avoid using too strong detergents, as they can damage the print. Avoid tumble dryers in favor of air-drying.

Second Procedure: Using a Heat Press Machine.

If you had already seen a heat press machine, you would have some idea about the device. It has a knob, meter, switches, timer, and handle. They all have different working instructions.

To start with a heat press machine, it would be beneficial to have previous experience with a similar heat press, as the tool is constantly being upgraded.

And the system for controlling the machine is also changing. A better-upgraded machine holds different systems.

It would be helpful to have a heat press to start with. Once you have decided to go with it, you should have to try it for the first. I hope it will change your mind!

You would have some ideas about the various heat press machines—each works differently with its manual gears.

What needs to start with a heat press machine

When you start transferring heat to certain fabric materials, you will use individual particles of your own. Those materials come with the heat press machine when you buy that.

Here, I include all those fundamental parts of a heat press machine that you need before starting with it,

The Heat press machine.

Are you determined to start your new t-shirt printing business and figure out where to begin? It would also be helpful if you opted for a heat press machine. The role of a heat press is becoming the most important part of the machine. Before buying one, you must check all the different types of machines in the marketplace.

You can easily find many of them online by searching.

Vinyl cutter

A vinyl cutter is a computer-controlled machine that cuts shapes and letters from rigid sheets. With a vinyl cutter machine, you can input any vector design that you want to put on your t-shirt.

Then the cutter will cut along the vector paths laid out in the design. When purchasing a vinyl cutter for your specific needs, consider your business, whether it is small or large. It would help if you purchased the machine according to that.

Heat transfer vinyl

Heat transfer vinyl is a single-color vinyl polymer sheet used to create an artistic design on fabric surfaces. In other words, it can be cut out and settled on specific subtracts for heat application.

It boasts remarkable advantages, including 3D puff, glitter, holographic, glow-in-the-dark, patterned, and reflective effects. When it comes to buying sheets, we need to choose the best option for optimal results.

Steps to get started with a heat press

When you are ready with a heat press machine, there is no more wait to start with it. Here are some initial steps to follow for your first heat press project. Just keep following,

Start the machine and heat it.

First, press the start button to heat it. You can find up and down arrows to adjust the hitting process and the temperature you would like to work.

You should have known the exact temperature for different types of printing material. That means the number of temperatures is not fixed. Know the same temperature for different kinds of materials.

Timer setting

Many heat press machines have a timer set to get warned of the estimated time to heat the engine. If your heat press has one, set the timer and stop it when the alarm sounds.

Select fabric and transfer papers

The heat press is widely used to print designs on the fabric. For your reason, you can use cotton, lycra, spandex, nylon, and polyester fabric.

Additionally, you have ensured the correct transfer paper is used for your machine.

Print the design on transfer paper

Once you have chosen your fabric and transfer paper, it is time to create some designs and have them printed onto the transfer paper. You can check if you have any pre-prepared plans on your computer.

You can also use a readymade design that is sold in the Market. Transfer paper with a particular technique to press or print on the fabric.

Place your fabric in the machine.

Place the fabric on the surface of the heat press. This step needs much understanding. Otherwise, you would have a failed run. When placing the material, ensure that your design is correctly set on the fabric.

Put your transfer paper over the fabric.

The transfer paper, in the shape of your required design, should have been placed on the fabric. It will allow transferring the design to the fabric. Make sure your material (is) is balanced when planting the transfer paper.

It may cause the design to crack in the area.

If you have just acquired a new heat press machine for your business, this guide will be of great help if you have no prior experience. Although the entire process will seem easy once you familiarize yourself.

It is a helpful way to start a business with a small investment. It will help you to make money within a few periods. However, starting with a heat press machine requires a high level of creative design knowledge.

Conclusion

We hope you’re convinced now if you were on the fence about further developing your printing business idea. Pressing a design onto any surface is straightforward, allowing you to express your creativity and make some money doing it.

Despite differences in shape, size, and function, all heat presses share the same basic mechanism. You’ve seen how to press a cap, shirt, and mug, but many other options exist. You can focus on tote bags, pillows, ceramic plates, or even jigsaw puzzles.

Of course, there is always innovation, so you are advised to pay more attention to this subject. There are many options for selecting the right transfer paper, and specific rules apply for sorting each surface type. But take the time to learn how to use a hit press, and you will be grateful that you did.

Find Here Related Articles About Heat Press Machine:

- Where to Buy a Heat Press Machine | Heat Press Machine

- Best Sublimation Heat Press Machine| Amazon Best Sellers: Best Heat Press

- Top 5 Best Mug Heat Press Machine Reviews in 2022 | Pros & Cons

- F2C Heat Press Reviews | 5-in-1 Combo Heat Press Machine T-Shirt Hat Cap Mug

- Mophorn Heat Press Machine Reviews & Buying Guide of 2022

- Fancierstudio Power Heat Press Machine

- ZENY Heat Press Machine 12″ x 15″ Pro 6 in 1 Combo Heat Press Digital Shirt Printing Press T-shirt Sublimation Printer

- Fancierstudio Power Heat Press 15 x 15 Digital Heat Press Machine |Sublimation Printer

- PowerPress 15″x15″ Heat Press Machine Industrial-Quality Digital Heat Transfer Press

- 7 Best Heat Press Machines for 2021 | Reviews and Guide

- The Best T-shirt Screen Printing Machine | Promo Heat Press Machine

- Zeny Heat Press 12″ x 15″ Pro: Best T-Shirt printing machine Reviews

- Silhouette Cameo 3 Bundle With Heat Press Expert Reviews, Pros & Con

- Screen Printing vs. Heat Press [Differences, Similarities, Pros, Cons]

Read More:

Leave a Reply

You must be logged in to post a comment.