All crafters know the thrill of using a vinyl cutting machine. It brings their artistic visions to life with incredible precision, enabling them to create intricate designs on various materials. Whether custom decals, apparel, or signs, a well-maintained vinyl cutting machine is essential to making the most of its lifespan and delivering consistent performance.

Think about beginning a new crafts project only to discover that your machine is not working properly or, worst of all, has broken down entirely. Today we will discuss the crucial aspects of vinyl cutting machine maintenance, equipping you with the information and procedures necessary to keep your equipment in top condition.

Understanding Your Vinyl Cutting Machine

No matter what your brand name is, such as Cricut, Silhouette, or another product entirely, understanding how your machine works can help with maintenance. Principally, they work in the same way, but each machine has its little idiosyncrasies. Let’s break down the major things to consider with maintenance:

- Blade: This is the core of your cutting machine. A dull or broken blade may cause uneven cuts, impacting your project quality.

- Cutting Mat: The mat is where the vinyl is positioned for cutting. A clean and sticky mat provides improved sticking of the material, resulting in accurate cuts.

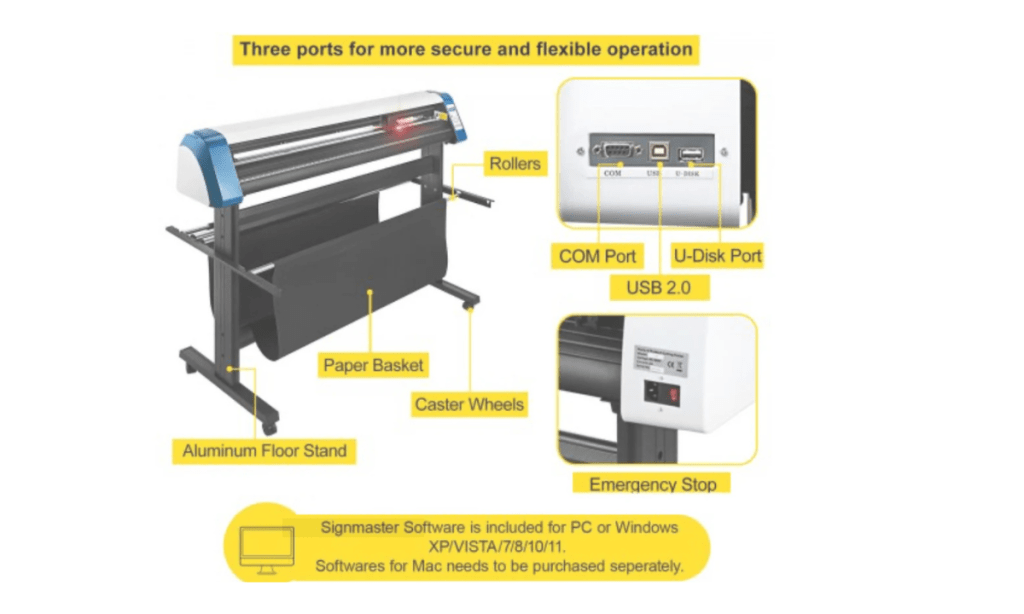

- Roller Wheels: These assist in feeding the material into the machine. Dirty or worn wheels may cause misalignment.

- Software: The majority of machines have special software that requires updating and staying clean on your computer for it to function well.

Knowing these parts allows you to understand which ones require ongoing maintenance when carrying out maintenance.

Routine Maintenance Tips

It’s not only about repairing your vinyl cutting machine when something goes wrong; maintenance regularly is also part of it. These are some tips that you will find useful to keep your machine in good working order:

1. Blade Maintenance

Your most crucial instrument is the cutting blade. Here’s how you maintain it:

- Routine Inspection: Check the blade for nicks, wear, or dullness. If there is any issue, replace it. A standard practice is to change the blade after approximately every 500 cuts, but that will vary based on the material.

- Blade Depth Adjustment: Ensure the blade is set at the right depth based on the material you are about to cut. This will prevent matting and unnecessary wearing of the blade.

2. Cutting Mat Maintenance

Your cutting mat should be susceptible to having debris on it, which reduces cutting efficiency.

- Daily Maintenance: Remove the leftover vinyl as well as other rubbish after each session using a scraper tool.

- Mat Washing: Wash your mat periodically using warm water and mild soap. Avoid the use of strong cleaners, and always air-dry completely before reuse.

3. Roller Wheel Care

Dirty or misaligned roller wheels can result in stiff feed and misalignments during cutting.

- Cleaning: Carefully clean the wheels with a soft cloth to remove dust and dirt. Mild detergent may be used, but not water-soaked.

- Inspection: Check occasionally for damage. If damaged, contact your manufacturer for replacement.

4. Maintain the Machine Free from Dust

Dust can be your worst nightmare. It accumulates on the machine components and can cause malfunctions.

- Regular Dusting: Use a microfiber cloth to dust the body of the machine regularly, especially before starting a new project.

- Covering the Machine When Not in Use: Covering your machine when not in use can protect it from dust accumulation.

5. Update Your Software

Keeping your machine’s software up to date is essential for:

- Efficiency: Manufacturers periodically release updates that make the machine faster.

- Bug Fixes: Any issues in older versions can be fixed with updates.

To update, go to your machine manufacturer website or software platform.

Troubleshooting Common Issues

Even with the best care, things can go wrong. Below are some common problems you might be experiencing and some advice on how to troubleshoot them:

1. Uneven Cuts

If your cuts are uneven, take a look at the following:

- Check Blade: Is your blade sharp? If not, change it.

- Examine the Cutting Mat: A faulty cutting mat will provide poor cutting. If it is no longer sticky or is broken, get a new one.

2. Material Skipping

If the material is skipping as it’s being cut:

- Test Roller Wheels: Are they filled up or out of alignment? Clean and inspect them. Make sure they are aligned when cleaning.

- Material Setup: Ensure that the vinyl is firmly fixed on the mat and that the feed mechanism is in good working condition.

3. Software Crashes

If the design software crashes continuously or takes an eternity to function:

- Update: Make sure that you update the software.

- Reinstall the software in case there are still issues, with a clean installation without any corrupt files.

Key Insights for Long-Term Care

Maintaining a vinyl cutting machine is not much different from caring for any high-precision tool that you own in your skill set. Here are the major nuggets that encapsulate the best practices in keeping your machine in top shape:

1. Establish a Maintenance Schedule

Having a routine maintenance schedule can help ensure that you’re always prepared. You may wish to create a checklist that covers:

- Daily: Clean the cutting mat and dust the machine.

- Weekly: Inspect the blade and roller wheels.

- Monthly: Update software and perform a more thorough clean on the machine.

2. Save Your Settings

Different materials require different settings, but it is time-consuming to set up each time. Save your default settings in the software so that you can easily access them, which will also remind you which settings to apply with which materials.

3. Invest in Quality Materials

Using cheap or substandard materials can lead to excessive wear on your machine. Buy good-quality vinyl, blades, and mats that meet your machine’s specifications.

4. Educate Yourself

Stay updated on tutorials, workshops, and forums about vinyl cutting, maintenance tips, and problem-solving techniques. Online groups on platforms such as Reddit and Facebook can provide valuable peer support and information.

5. Listen to Your Machine

Just like any piece of machinery, your cutting machine will frequently provide warnings when something is amiss—pay attention to strange sounds, and notice changes in performance. Fixing things at the first sign can avoid larger issues later.

Personal Experience: A Journey in Crafting

As a crafter who’s spent hundreds of hours with my vinyl cutting machine, I’ve learned that failing to do even the most basic maintenance can cause annoying mishaps. I once hurried a large project for a friend’s wedding, eager to cut custom decals for party favors. I forgot to inspect my blade, and it was dull my designs were jagged and incomplete.

Following a quick trip to my local hardware store for a new blade, I discovered the benefit of having spare parts on hand. Since then, I have developed the habit of keeping not only spare blades but also mats and other devices readily available. The extra effort I take in maintenance now saves me time and worry in the future.

Conclusion

Regular vinyl cutting machine maintenance is the key to ensuring your machine operates at peak performance and remains in service for years to come. With an easy but regular maintenance routine like routine checks, cleaning, burr-free blades, and updated software, you’ll have your machine primed to tackle whatever project you throw its way.

By integrating these practices and learnings into your workflow, not only do you enhance your craft experience but also establish a long-term relationship with your tools. Work on your next project without the threat of technical glitches, and allow your imagination to radiate through.

Leave a Reply

You must be logged in to post a comment.