All screen-printing machine users should know how to use screen printing machines to get better output. Welcome to the best user guide for screen printing machines. Let’s dive into the middle.

Screen printing is pressing ink through a stenciled network screen to make a printed design. It’s a famous strategy utilized in various industries. Regardless of whether you’ve never heard the phrase before today, you’ve probably used or worn a screen-printed item eventually without understanding.

The cycle is sometimes called serigraphy, yet these names allude to a similar fundamental technique. Screen printing is terrifying at the start. But it is a lot simpler and more accessible than it looks. One can quickly launch a screen-printing business at home without any difficulty. The entire process is relatively inexpensive.

This article will guide you entirely in using a screen printing machine. Check out the below-listed step-by-step guide for detailed insight.

Steps on How to Use a Screen Printing Machine?

The screen-printing process involves different methods, but they all use a similar basic procedure. Some of the basic steps involved in this process are as follows:

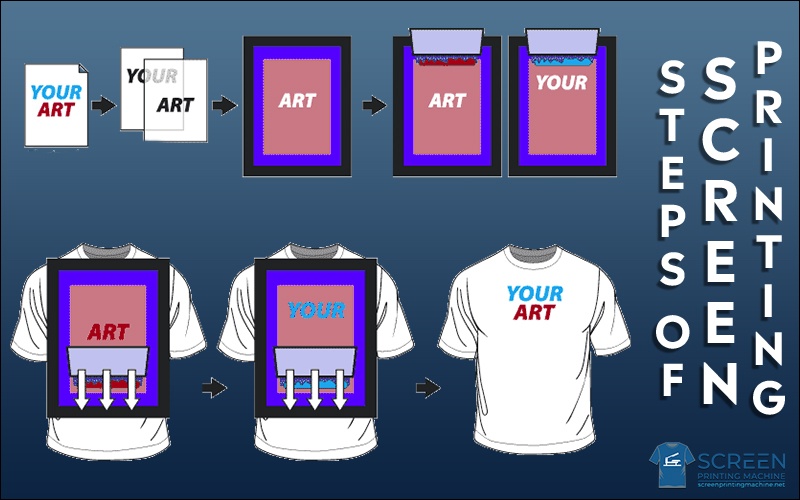

1. Create a design first

The first step is to create a design. Your design gets printed onto a transparent acetate film, later utilized to produce the stencil.

2. The screen is arranged.

Once a design is created, the next step is to arrange the screen. The printer needs to pick the right kind of mesh screen to ensemble the stylistics of the texture and the design of the fabrics being utilized. This mesh screen is then covered with the light-reactive mix, which will ultimately consolidate as it’s prepared underneath the bright light.

3. The mix is exposed

In this step, the mix is exposed. An acetate pane with the design is positioned onto the emulsion-covered mesh and is later out to a bright beam. This light will solidify the emulsion so that all the screen parts enclosed by design will continue in a liquid state.

In case more color is utilized in the design, a new display (must be used) for every color. Every screen must be associated with precision by hand.

4. Stencil (is formed).

In this step, the mixture is washed off, and the pattern is shaped. Once the correct time frame has elapsed, every screen region that is not covered by the design will go hard. Any emulsion that has not solidified should be flushed away. That will bring a clear imprint of the plan on the screen for the ink to pass through.

5. The screen is dried

In this step, the mixture is washed off, and the pattern is shaped. Once the correct time frame has elapsed, every screen region that is not covered by the design will go hard. Any emulsion that has not solidified should be flushed away. That will bring a clear imprint of the plan on the screen for the ink to pass through.

6. Item prepared for printing

In this step, the screen sets against the printing press, and you must place the item carefully against the printing plank underneath the screen.

7. Squeegee and inking

In this step, the screen lowers against the printing panel, where ink is included at the top.

A squeegee is used for pulling the ink across the screen’s total length. This interaction pushes the ink through open regions in the stencil, bringing the design engraved onto the item.

This entire process is repeated in the case of multiple items. Once everything is complete, the emulsion is detached using a washing liquid. The mesh can afterward be used to produce a new stencil.

8. Check, Dry, and Finish

- Check, Dry, and Finish

That is the final stage of the printing process, where you will see the printed product and garment passed through a dryer.

The ink is adequately cured in this step, ensuring a smooth finish, and the finishing product is value-checked and washed properly to eliminate any outstanding residues.

Do you need to make your next screen printing project? If so, remember to check out our all-in-one screen printing machine.

Why is Screen Printing Used?

We generally utilized the screen printing procedure because it produces clear tones, even on darker textures. The ink or paint also lies in layers on the outer layer of the surface or paper, giving the print a pleasingly tactile quality.

The strategy is also preferred because it permits the printer to replicate a design easily on different occasions. Since a similar stencil can be utilized to duplicate a design repeatedly. It’s beneficial for making numerous duplicates of a similar article of clothing or frill, which makes screen printing an exceptionally proficient strategy for making large batches of custom apparel for sports teams and work uniforms.

Will Screen Printing Ink easily wash out?

Assuming that a garment has been appropriately screen printed by a trained, proficient individual utilizing washable ink, then, at that point, the design shouldn’t come out. To guarantee a (colorfast finish), “the printer” must ensure that the maker’s rules are set for the ink. The proper drying temperature and time shift are contingent upon the kind of ink and the texture utilized, so the printer needs to precisely adhere to the directions to make a durable, washable thing.

Conclusion of the screen printing process

Screen printing is excellent for those hoping to print onto darker-hued textures. A profoundly adaptable cycle lets you print on wood, glass, metal, paper, surface, and plastic to involve a standard stencil in progression. It is an extraordinary printing process for bulk requests.

This article contains a complete guide about screen printing and its steps.

Related article you may like: Best screen printing machines for t-shirts

Best commercial screen printing machine

Leave a Reply

You must be logged in to post a comment.