The printing business is both rewarding and challenging. You will set up your print shop by avoiding the most common screen printing mistakes.

Influential companies in the Commercial Screen Printing industry and adjacent industries have large Market shares. Or it is developing new business models and methods that could disrupt.

Those who have been in the industry for years will admit to making screen printing mistakes that cost their business both time and money. While mistakes happen no matter how diligent you are, it remains vital to do your best to avoid them.

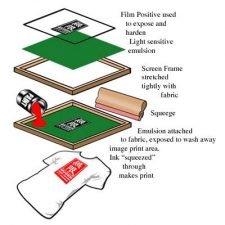

Screen printing is an indigenous part of a screen-printing business. Most beginners make mistakes in screen printing. Here, we will discuss some common errors in t-shirt printing, custom apparel printing, and how you can maximize your profit by starting a screen printing business. Some common screen printing mistakes can occur, eroding your profits.

It would be helpful if you avoided these blunders. Otherwise, you could not only spare yourself from some messy situations but also save on time, money, and materials. Therefore, we believe it is essential to be aware of these common screen printing mistakes associated with the screen printing machine and avoid them to gain a great head start in on-screen fabric printing. If you’re a newbie or planning to start your screen printing business, this article will be beneficial to you.

Lack of Master Plan:

First, you must gather knowledge about the screen printing business and create a solid master plan. We know that preparation is the key to establishing a reliable printing business. You should know what type of screen printing equipment and materials you need, how much time you will have to spend, who your customers are, and how to clear the basics of the screen-printing business.

Use of Same Screen Mesh for All Screen Printing Jobs.

Most screen printing machine manufacturers provide only one type of screen mesh for all their jobs. In general, the screen printing manufacturer typically provides screens with mesh counts of 110 and 125. These meshes will be the ideal solution for everyday color printing.

On the contrary, some users will print on halftone and high-end photorealistic printing, which is very harmful to a screen printing machine. If you want to print on halftones and photorealistic images, you need to use a higher mesh, typically ranging from 190 to 230 mesh for the underbase printing and up to 305 mesh for color printing. When you decide to start your printing business, you should use a wide variety of mesh for high-quality work.

Not Cleaning Equipment Properly:

If you want to keep your screen printing business running smoothly, you should clean all your equipment correctly every day after completing your job. Generally, the speck of ink remains frozen after your last printing, is a piece of lint from your previous substrates, and contains some grease and smudges from your hands.

All garbage can create a spot on your substrates and corrupt your final products. You can save a significant amount of waste by cleaning your equipment properly and regularly. It would help to wash your plates well, so the press is dust-free. On the production floor, it is essential to practice regular hand washing. Otherwise, your hand can spread ink, dirt, and grease onto your substrates.

Checkout:

Power Press 15″x15″ Heat Press Machine Industrial-Quality Digital Heat Transfer Press

Using plastisol ink straight from the can.

When choosing ink for your screen printing machine, be very careful. Most ink companies have offered assurances that their ink is ready for use, although some companies’ printer inks are very creamy and work well with high mesh screens.

However, some ink companies produce ink that is too thick, and you need to add a reducer to thin it for a creamy and smooth finish. So, if you want to use plastisol ink, you need to reduce it so that the ink works effectively with your high-mesh screens and can handle all of your multi-color jobs.

Using too much ink.

You cannot do any work from your printing machine without ink, which is very important. Sometimes, you may need to make a few attempts to find the right amount of ink to use each time. But if you are a beginner, you don’t need a lot of ink. You can take a few spoonfuls of ink.

That may be enough for you. Sometimes you will face big trouble, like managing the ink. Remember that when printing with water-based inks, the screen floods with it and doesn’t dry out between prints.

Not using the spot gun.

A spot gun is essential before buying any screen printing machine. Sometimes your final product will be affected by stains or spots. You can save the spot gun by applying it. If you don’t have a spot gun, you may be unnecessarily wasting products.

This gun will also help you clean solvent from fabric flaws, including grease spots, stains, and ink prints.

Using Backdated Equipment:

When you want to provide top print quality and attract more customers to your printing business, you need the essential equipment so that you can replace any part of the machine at any time. If your t-shirt printer can’t set up with the four-color press, consider using the six-color press for improved output. Sometimes you may need to print on halftone.

Then you can use a laser or inkjet printer to provide excellent quality. If you want to reach the final level of the printing business, undoubtedly, you need more color to consider your exposure unit and film output.

Not Doing a Test Print

It is one of the crucial steps, but many screen printing machines will skip this to save production time. That will be an extra step, but it can save you from wasting time, energy, and materials. You will make significant mistakes if you don’t conduct a test before making a purchase.

When you test any printer, you can identify and correct problems before they impact the entire job. For example, you can check for bad registration, improper color matching, poor placement, spelling errors, or logo mistakes within the print itself. Therefore, you should always perform a test print, even if you have been printing for some time. That could save you from throwing out an entire press run.

Using White Underbase as a Highlight

If you want to use the white under base as a highlight, then leave this idea immediately. When you use the white under base as a highlight, you need too much ink, which produces a heavy hand that may be undesirable and affects the quality of the following layers of ink. So it would help if you extra effort to prepare a separate screen for the white highlight.

Don’t Press on the Squeegee Too Hard.

We know that you need a firm grip on the squeegee to get a great coat of ink. That means not saying that you put your whole weight onto it. If you push too hard on your machine, you may encounter issues like ghosting or smearing, so avoid doing that.

Mophorn Heat Press Machine Reviews

Best Heat Press Machines Review & Buying Guides

10 Best T-Shirt Printing Machines to Buy

Fancier studio Power Heat Press 15×15 Sublimation Digital Heat Press

Leave a Reply

You must be logged in to post a comment.