Don’t settle for mediocre equipment.

There’s a lot of inexpensive and second-hand screen printing equipment available to help you get your screen printing business up and running at a relatively low cost. However, buyer beware: there’s plenty of defective equipment to be found, and faulty equipment can result in poor prints.

A full-scale, multi-station automatic system may be unobtainable and unnecessary when you’re just starting. Still, it would be helpful if you had the equipment to produce high-quality prints as your business grows.

Conduct thorough research to determine the equipment and supplies that best suit your current needs and goals. Choosing the right equipment and supplies will help you establish your reputation and save money by avoiding wasted misprints or unnecessary equipment replacement.

5 Useful Tips for Screen Printing Machine Users

It doesn’t matter what type of screen printing machine you use. You must follow the proper printing rules to get standard screen printing artwork. Screen printing is quite challenging for beginners. It can be tough enough for new entrepreneurs.

Most of the time, they fail to give high-quality screen printing work. A screen printer must select the correct type of screen and keep the screen taut while printing. After printing, the screen needs to be dry. Finally, he has to apply the emulsion. Mix the emulsion 2 hours before printing.

The Demand for Good Quality Screen Printing

Screen printing is puzzling. In this current century, its use in screen printing shops, garments, ceramics, and glass industries is increasing dramatically. It’s also gaining popularity in the wood and metal industries.

Many printing industries have expanded worldwide, with a focus on screen printing. Screen printing businesses and industries are going forward at full speed. The demand for high-quality printing work has reached its peak. Only a good piece of work can ensure your sustainability.

What to do as an amateur screen printing machine user?

As a beginner, a printer must need to follow some basic screen printing methods. He needs to avoid frequent mistakes.

He might need to cope with critical situations. So you must have an excellent hand to run the screen printing press. Your work must be quality and unique. There are many ways to be successful in screen printing, but you may get good direction from the few pieces of advice below.

Making a Clear and Simple Design to Get the Best Printing Work

You can easily use a simple design on a t-shirt, garment, silk, or glass using printing techniques. A transparent print work increases your design acceptance, which will be considered the artwork of printing.

It would help if you always tried transparent printing a simple design. It would be preferable if you could give the thick line with a clear print.

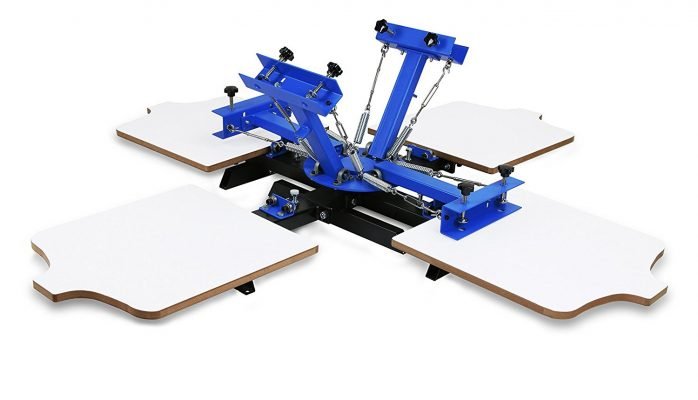

Screen Printing Machine 4 Color Silk Screen Printing Machine 4 Station Adjustable Devices Press Printer DIY Shirt Equipment (4-colors 4-stations)

Essential Tools for the Screen Printing Machine

The essential tools for screen printing machines are the emulsion, the ink, and the squeegee. After creating a clear and straightforward design, a screen printer needs to gather some valuable materials.

It needs to select a printing object, such as a garment, bag, t-shirt, glass, ceramic, or metal. The printing object should be transparent, and it might be able to absorb the ink.

Then, you gather black paper, photosensitive emulsion, activator, ink, plastics or fabrics, and a squeegee.

Building a structure or a Screen Printing Frame

Creating a screen printing frame is another crucial step in the screen printing process. This frame or structure will allow the ink to pass through the screen onto the printed object. Frames may be of different materials or be wooden.

A wooden frame is suitable for a quality screen mesh. To build a wooden frame, you need the following materials.

1. Plywood and clamp hinge 2.)Wood screw 3.)Lumber and duct tape 4.)Foam rubber (thick) 5.)Drill and glass plates

Take the plywood, which is 2 inches long and larger than the frame. After that, I suggest you take a foam rubber whose length is 3″. It would help if you kept a 1/2″ gap between the frame and foam.

The screen printing machine users should hold the frame in the center with Plywood and keep the clamp hinges on the other end. Then he needs to take a 1/4″ glass plate, the same as the frame. Of course, he should cover the glass plates with duct tape to ensure safety.

Mesh count or screen

You can’t ignore the importance of the correct mesh count in screen printing. It is the most critical consideration in the screen printing process. A crucial fact is to choose a suitable screen made from metal, nylon, plastic, polyester, or vinyl. Among all these screens, plastic screens are the most ideal for the frame. Metal screens are beneficial for the industry.

Applying Photo Emulsion

You can’t but apply Photo emulsion to burn the image. Photo emulsion is a type of liquid chemical that is sensitive to light. The manual screen printing machine burns the image and creates a design. It is used for the screens and blocks the region in which the ink passes. The emulsion should be poured on the screen thinly, and the users should be instructed to cover all the holes.

Read More Related Articles:

- 10 Best Screen Printing Machine Reviews and Buying Guides

- 5 Useful Tips For T-Shirt Screen Printing Machine Users

Leave a Reply

You must be logged in to post a comment.