The emulsion is one kind of light-sensitive element that works to block the ink on the screen. It is challenging to burn the image with emulsion while you print tons of t-shirts. Most screen printing machine users make a mistake in applying the emulsion correctly.

To achieve high-quality screen printing, a printer must apply emulsion evenly and adequately. If he fails to do so, it will be the cause of your failure in quality screen printing design.

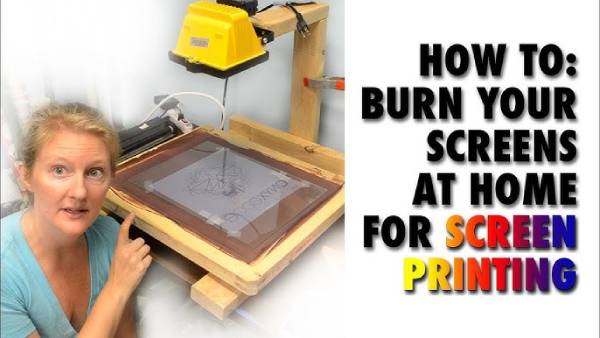

Screen printers should follow some basic guidelines for applying emulsion to avoid failure in screen printing. In a tight mesh, the negative of the image needs to burn evenly. The meshes should be stretched between the screen and the frame.

Before going into the application of emulsion, let’s see why you have to apply emulsion properly. Due to improper use of the emulsion, breakdown and pinholes occur. It causes headaches for many users of screen printing machines. In the case of a considerable number of orders and under pressure for the deadline, it brings more frustration for the screen printers. A wise approach is to create a new screen, as it takes time to create one.

How to solve the problems of applying emulsion for screen printing on the screen?

Don’t worry. In the ongoing screen printing process, a crucial element for screen printing press users is applying the emulsion. The steps below will help you use the emulsion correctly to create a unique photographic design on the screen printing machine.

- Initially, you need to select the correct type of ink for the specific screen.

- Then, you need to ensure that the screen used for printing is stretched tightly. Good consistency and quality are assured for the tight tension of the screen.

- After that, you have to mix the emulsion two hours before applying it, and allowing 2 hours will prevent the creation of air bubbles. The air bubble may create a pinhole problem.

- Green or other degreasers can be used if it is needed.

- The screen must be completely dry before coating it. You can use a sharp scoop coater.

Be careful about coating. While you’re coating, keep facing the scoop coater of the t-shirt. They go for the side. Finally, you have to dry the screen from the side down. When

Once fully dry, you start printing t-shirts on the t-shirt printing machine. Applying emulsion in these ways can make your printing press successful.

The emulsion prevents printing in the ink-blocked area, making the line crisp. To create a proper design, the proper application of the emulsion is essential.

Leave a Reply

You must be logged in to post a comment.