Are you searching to buy the best manual screen printing machine for your small business or screen printing workshop? There are several factors to consider before starting your custom screen printing business, whether with a manual screen printing machine or an automatic screen printing press.

These include the number of colors in the design, the size of the order, the deadline for completion, and whether you plan to repeat the same design.

The key facts below will help you choose the best manual screen printing press.

The manual screen printing press has various stations and colors, from single to twelve. However, most professionals prefer to start a non-commercial or home-based screen printing business with 4- to 8-color silk-screen printing machines.

It would be helpful to start your first screen printing business with a manual press. Therefore, you must select a manual media that meets your screen printing needs. Beginners or new screen printers should start with a manual screen printing press to develop the skills necessary to grow their business and bring their latent talent into the sector.

Key Facts Of Choosing

For custom apparel (screen printing companies), you will get two types of screen printers: manual screen printers and automatic screen printers. So, what’s the best choice for your custom screen printing business?

How can you get the best manual press?

As you are a newbie in manual screen printing, you need more ideas about the screen printing press. For a newly established screen printing shop or a screen printing business, screen printers should look forward to purchasing a manual screen printing press with good working capabilities and a micro registration system.

First, you must identify your requirements to choose the right manual screen printing press for your shop. What’s the best way to narrow your options to get the best manual machine? Let’s address a few questions.

What would be the screen size of the print area?

You may need a different size print area to print oversized full fronts or extra-large prints. You may find a manual screen printing machine with a handle that accommodates screens ranging from 25″ to 36″, capable of printing up to a 20″ x 30″ print area.

How many colors do you require?

Nowadays, screen printing needs more colors. Anyone with a reasonable budget can buy a 6-color, 6-station, or 8-color manual screen printing press.

What size manual press can you accommodate?

Accommodation isn’t less important for buying the manual press. Ensure you have sufficient space in your shop for the manual machine, apparel boxes, job cart, flashes, and other necessary screen printing supplies and equipment.

Features

- Up to 3-way (front/back, left/right, and rotational) fully functional, professional gauge, micro registration

- The sidebar screen clamps to facilitate press registration and virtually eliminate frame/mesh stress.

- Prefer back/rear clamps, some manufacturers will offer them instead, or even a combination of side and rear clamps.

- All heads down at no extra charge will allow you to print on multiple heads simultaneously, given the same number of print heads and stations. Even on a 6/4, you can print on two heads simultaneously.

- Full-size (16″ x 22″) rubber-coated aluminum pallets cover most t-shirt and sweatshirt needs. The rubber coating allows for quick cleanup and helps prevent pallets from overheating.

- It had Ideal rotational weight without sacrificing strength. Often, the claim of “built like a tank” only increases the operator’s muscle fatigue and reduces production.

- Compression-style adjustable tension springs that will not break. Other styles of springs are susceptible to breakage and possible injury.

Justify the Work Ability of the Manual Screen Printing Press

It would be helpful to purchase a manual screen printing press that has a well-working capability and isn’t physically unfit, as the printer manager handles manual press needs.

A screen printer must do the entire job of pulling and pushing the squeegee. The carousel rotates, with the lit print head, etc., being manipulated by hand. For a larger order, he has to work all day long.

That’s why, before buying a manual screen printing press, you have to think about a screen printer that can justify the workability of the media. He must be solid and smooth enough to rotate the carousel easily.

Space for the Manual Screen Printing Press

As a beginner, you can start with a few screen printers to launch your business from a limited space, such as your garage or home. In this case, you need to consider the area where you will place the manual press you plan to buy. It doesn’t require extra equipment, such as an air compressor or chiller, to provide power (excluding the specific type of presses).

When you are ready to start your small business with a layout, you have to think about the operator of the press. Around the press, keep a comfortable space for running the press nicely. You must keep your manual screen printing press, conveyor dryer, and exposure unit.

Types of manual screen printing presses

There are various types of manual screen printing presses, categorized by their stations and colors. A one-color, one-station tabletop manual (screen printing) press takes up a small space. Anyone who wants to go for a large setup for professional printing must think larger area.

You can choose a 6-color, 6-station screen printing machine according to your professional budget. It is wise to run a 4-color press if the 6-color is complex for you and remains open for one or two stations. As almost all maximum designs in screen printing are less than 4 colors, the 4-color, 4-station silk screen printing press is the best alternative to the 6-color press.

Things to Check out Before Buying the Manual Screen Printing Machine

Although the manual screen printing press appears simple, its specific models can differ. When buying a piece of equipment, it is a good idea to check out the models and features that the brand offers. It would help to compare the following keys while looking for the best manual screen printing press.

- Pallets

- Clamps

- Micro registration

- All Heads down

- Off Contact

- Spring Tension lit

Pallets

Check if the pallets are suitable for all types of printing, such as child or umbrella sizes. That will allow you to handle any order you get.

Clamps

Check whether the clamps have screened on the sides of its back. Is it preferable to the type that you want, or match and mix? Does the manual screen printing machine have the option of pneumatic screen clamps?

Micro registration

Micro registration allows for multi-color designs. Make sure that your press is precise with the micro roll.

All Heads down

Make sure all the print heads of your machine can be down. It will let you print all plates at once. It also increases your production capacity, as multiple people can work on the press simultaneously.

Off Contact

The vertical distance from the screen and printing layer is known as off-contact. Ensure the manual screen printing press is in off contact. You have to keep different spaces for different printing materials.

Spring Tension Load of the Manual Screen Printing Press

Screen tension is a vital agent in the printing industry. Check that your press has this tension, as it helps to lift the head of the screen printing press smoothly and efficiently.

Let’s take a look at two of the Best Manual Screen Printing presses.

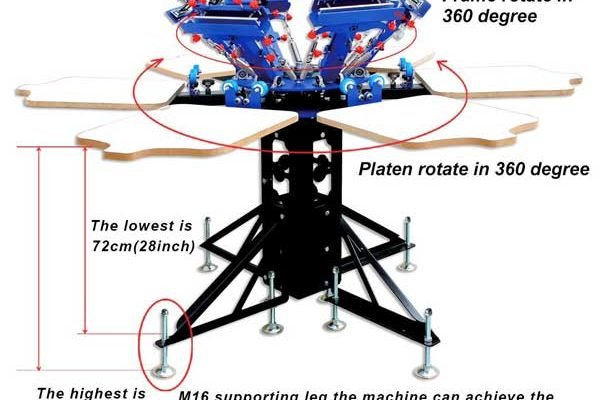

- 6 Color 6 Station Double Wheel Screen Printing Machine T-shirt Heavy Duty DIY

This 6-color, 6-station manual (screen printing) press, the best t-shirt printing machine, is easy to operate and works well. It has adjustable spring devices that can easily move up and down according to the weight and size of the screens. This manual press gives you the security against improper spring intensity to prevent squeegees from expelling and

The weight of the press is a bit high, but it guarantees screen unfixing and ink splashing at a higher intensity due to the importance of squeegees and screen frames in maintaining loose power. The manual screen printing press height is approximately 35 inches (90 cm), and it is a micro-registration screen printer.

Pros:

- It is cumbersome and made of steel.

- The frame of the press can rotate 360 degrees.

- The platens can also turn 360 degrees.

- The machine can be adjusted to 8 inches (20 cm) as it has an M16 supporting leg.

- The press is suitable for those operators whose height is 1.6 m to 1.8 m

Cons:

- Need much room for height adjustment

- The price is a bit high for the beginner.

Recent Buyer Reviews for the 6 Color 6 Station Double Wheel Manual Screen Printing Machine

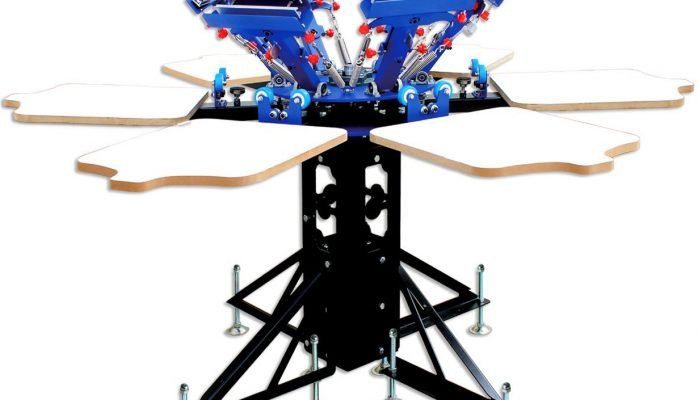

2. Double Rotary Manual 6-6 Colors Silk Screen Printing Press Machine Printer T-shirt Heavy Duty DIY

6-6 Colors Silk Screen Printing Press is a new type of manual t-shirt printing press. It would be the best choice for colorful printing. Compared with the original t-shirt heavy-duty DIY printer, this t-shirt heavy-duty DIY machine has a micro-registration function. The new design metal stand can adjust in height from 28″-35″. To create precise color matching, you can use the small red handles to move the screen frame slightly to the right or left.

Product Description

- 6-6 Colors Silk Screen Printing Press is a table-type.

- The design of the press is combinatorial, and it saves space.

- And convenient for transportation.

- Adjustable double-spring devices are available with the press and are usable for different weight screen frames.

- Max frame size capacity: 16″x20″(40cmx50cm)

- The screen clamp can be moved up and down,

- Suitable for screen frame within 1.2″ (3cm) thickness.

- All-metal construction,

- advanced electrostatic spraying and electroplating,

- It’s durable, easy to clean, and rust-resistant.

Parameters

- Platen size:45*55cm(18*22inch)

- Machine size: 190*190*110cm/74*74*43inch

- Net weight: 152kg/334lb

- Gross weight: 162kg/335lb

Double Wheel Manual Screen Printing Machine T-shirt Heavy Duty DIY

Read the 10-best screen printing machine reviews and buying guides.

That is suitable for tiny businesses and smaller printing production. Unless your company is large, you shouldn’t use the automatic press.

Manual Screen Printing Machine VS Automatic Screen Printing Machine

An automatic screen printing machine requires ample space and is more expensive. Manual screen printing press saves both money and space. A manual press doesn’t require electricity and an air supply. However, the manual screen printing machine, which has a particular configuration like pneumatic screen clamps, requires both an air supply and electricity.

After printing a (number of) quality artwork with your manual equipment, your small business can achieve the trust of your clients. You can take a lot of orders, and you can increase the number of presses. Gradually, your business will transfer to a good position.

Thus, you can print a massive amount of artwork with solid printing with your manual screen printing press. As your business grows, you can start using the automatic screen printing press. You can make buying manual equipment easier as it is within your budget and the right tool for your business.

Leave a Reply

You must be logged in to post a comment.