Different Types Of T-shirt Printing Methods

Before starting your custom t-shirt business, you should learn which t-shirt-(making method) to use. Though the t-shirt screen printing machines and heat press machines are the two most popular and bking most common presses to design custom t-shirts, you will learn 3-more unique t-shirt printing methods here.

Here are the most popular 5-different printing t-shirt Printing methods:

Here are the most popular 5-different printing t-shirt Printing methods:

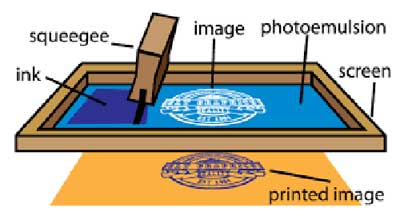

Screen Printing:

Screen printing is the most popular (t-shirt)-making method with pros. Another name for this screen printing design is silkscreen printing. In screen printing, you can make t-shirt designs with the help of a stencil and nylon mesh. To create a t-shirt design, you must block the negative space with waterproof material.

For this method to work, you will need a stencil and a nylon mesh. You set up the stencil, which (is) held by the nylon mesh. Waterproof material will block the negative space that you want to design. You have to dye only the negative permeable space.

The screen printing or silkscreen printing process is a standard method to make high-quality t-shirt designs as it allows reapplying the same designs. You can easily impress your customers by providing a unique t-shirt design through screen printing.

Today, most t-shirt business owners use t-shirt screen printing machines for mass t-shirt design productions. If you want to use them at home for a single or unique design, it’s possible.

If you want to buy the best t-shirt (screen printing) press, then watch our top 10 best screen printing machine reviews.

Direct To Garments(DTG):

Direct garments (DTG) is a popular t-shirt printing method among hobbyists, like the screen printing method. Though the process is easy, you must earn enough knowledge if you are not taking support from professionals. You require a DTG printer and ink to work with this process. Directs to garment printers are like paper printers. The difference between paper printers and DTG is that the ink is (being) used in the fabric. In this method, you have to take help from a computer. You have first uploaded a t-shirt design to the computer to create a unique design.

You can design a super complex t-shirt design with the direct-to-the-garment printing method. This DTG will help to make soft-feel designs as the ink won,t create an extra layer on the shirt.

Dye Sublimation Printing:

This dye sublimation printing method is suitable for light t-shirts or garments. Though it is costlier, it is best for professional t-shirt printers.

You can get the best quality output like an expert printer if you have good knowledge of dye sublimation. This method works well for printing on polyester fabrics. To make designs with this method, you will require dye-type liquid, which dries up and meets the t-shirt design. Once it gets dried and solidified on the fabric, you must apply pressure and heat with a sublimation heat press machine. The dye sublimation printing method is excellent as it helps you to make a cute look and durable t-shirt design.

Tour the 10-best sublimation best heat press machine reviews and buying guides.

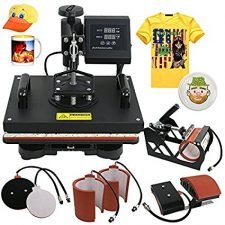

Heat Press Printing:

Heat transfer machines are now top-rated among small t-shirt (printing business) business owners or those with limited t-shirt printing orders. It is very economical to make t-shirt designs with heat transfer press machines, saving time and resources. This process uses heat transfer paper to make durable t-shirt designs.

To buy the best t-shirt heat press machine for small businesses, visit our 7-best t-shirt printing (heat press machines).

4 Best T-Shirt Printing Machine Reviews and Buying Guides

4-best t-shirt screen printing machines to buy in 2024-25

BestEquip T-shirt printing machine Swing Away Heat Press Machine for T-Shirts

The BestEquip t-shirt heat press swing away is a solid transferring machine that can transport pictures and letters on-Cotton materials, Fiber, Metals, Ceramics, Glass, etc. As per your choice, moreover, you can utilize it to print letters, numbers, and images on T-shirts, bags, mouse mats, jigsaw puzzles, ceramic tiles, and plates. The temperature of the BestEquip Heat Press runs from 0- 480 degrees Fahrenheit.

This t-shirt maker machine keeps a digital time and temperature control to ensure the settings are exact and appropriate for the explicit material you need to transfer.

If you need the best t-shirt printing machine for home use, this machine is suitable as it appears with an LCD screen to give you a view and read the works of the device. There also has an audible alarm to signify the time up of the transfer. As a result, you can prevent overexposure to heat.

The swing-away design offers you to observe the entire work spot during the transport in the procedure. It also makes you sure of the safety of your hands. Therefore, you need to work more straight with the heating elements.

The best equip Swing Away Heat Press ensures that their download is smooth heat distribution throughout the entire working spot.

Zeny Heat Press T-shirt Press 12″” x 15″” Pro 6 in 1 Combo Heat Press Machine.

It is such a heat press machine that has multi-functional quality. So you will get a better return on your investment. The body builds with strong steel parts to ensure dependability and permanence.

You can adjust the height to transport shirts, sweatshirts, and stuffed animals without minding their thickness.

This t-shirt printing machine is (mainly) built to be dense in size, so it takes less space. As a result, it might be the best T-Shirt Printing machine for small businesses. That will give you the advantage of storing it anywhere. Safety (is) secured with no burn as the swing-away design rotates 360 degrees.

The time and temperature movements are to (be) monitored with the dual digital controller.

![]()

Promo Heat 15×15 Sublimation T-shirt Printing Heat Transfer Press Machine

The Promo (Heat press) 15-inch x 15-inch Sublimation T-Shirt Printing Machine will allow you to plan your own, Mousepads,-Customer T-shirts,-License plates,-Tote bags-Other different items.

As it arrives completely assembled and prepared to operate so you will not need to be anxious about creation faults. A digital LCD timer will allow you to place the correct temperature and time for each of the materials you need news to transfer.

An audible alarm is set, which beeps, finding the preset time (is) passed. As a result, you would indeed have nothing overexposure to heat. Teflon coating allows resistance to sticking surfaces by preventing the scorching of transfers.

Gecko Heat Transfer Heat Press Machine, 16 x 20-Inch, Black

Besides being reliable, it as well lasts for a highly extended time. It gets heated up in just 20 minutes and arrives at 350 degrees Fahrenheit.

The additional Teflon sheet with an instructional handbook will guide you throughout the procedure.

It gets attached with an installed non-stick with having 16 x 20-inch heat plate taking a complete set of heating coils so that constant heat distribution is possible.

Operating this T-Shirt Printing machine, you will get the chance to bear out various types of transport on materials that could get reach 5/8 inches. It only requires a little try while used as the existing freshly featured lifting instrument.

This machine is (also) bordered by steel frame construction with adjustable pressure knobs at the base.

You read this and now click and start your T-Shirt Printing Business.

CAD Cut Vinyl Printing:

This method uses vinyl cutting machines to make soft clothing and unique professional designs using a CAD cutter and special software. Then you have to use it to design the t-shirt with a heat transfer method.

This vinyl printing process helps you print longer-run and one-off designs and is suitable for multiple types of garments. The vinyl cutter (heat transfer) vinyl assist you in making sportswear, tiny graphics, slogan, and different layers to print various colors of the design.

Visit our 8-best vinyl cutting machine reviews.

As an entrepreneur with T-shirt Printing Machine, you should first learn some methods to print. Usually, there are three methods mainly used, so as a fresh entrepreneur, you also advance with these three ways-

These three methods are – 1. Print with Transfer Paper. 2. Image Transfer with Photo Emulsion Process. 3. T-Shirt printing using Ink dyes.

Print on Transfer Paper Using T-Shirt Screen Printing Machine

Step1: image titled Print on the T-Shirt

Procure T-shirt transfer paper. Choose from two types of transfer paper per your need, one appropriate for white or pastel shirts and another suitable for every darker color. Collect paper as per your required size.

It is better to use light transfer paper to print light or white shirts; for any sweater with a dark color, you can use colored transfer paper.

Step 2:

Please choose a model; you may take it from pictures stored on your computer. If the image is in a physical structure, make it scanned and then save or keep the image on your PC by taking a good photograph.

Step 3

The image is to (be) taken in the mirror. Then your shirt will receive a mirror effect, and then with your print options window, take a setting for that particular image. In case of not do this, all your text where the design (is) kept will be unreadable.

It reverses the image using transfer paper for dark shirts and transfers it as per the appearance. Making a demo on the test piece or regular paper is wise.

Step 4

Make your design Printed on paper. Previous to printing, make sure that the image fits on your paper. If it’s enormous, pick “fit to scale” in the print options. Use the proper printer.

The print is blank when the two sides of your transfer paper appear dissimilar. One side could carry a logo, design, or thermal indicators. Switch to “landscape mode” when the image is full, then it is high. if you buy baby Leggings visit here Best Leggings for Tall Skinny Little Girl

Step 5

Cut the image. Any paper you depart around the image will illustrate up as a thin film on the shirt. To make a fresh picture, cut out the image. To obtain an exact cut, use a ruler and a proper knife.

Step 6

Wrap a stable, flat surface with a cotton pillowcase. Clear the table after that clean and dry it if required. Put a cotton pillowcase over this outside, and cover enough space to lay out the region of the T-shirt you will print. Most ironing boards are not appropriate, as are the metal bars or grating on the outside.

Use an exterior that can resist temperature. Don’tDon’t attempt to iron over a laminate countertop. A cutting board is a suitable one.

Step 7:

Place your Iron. Make sure the advice appears with your transfer paper to determine which settings work best for your manufactured goods. When there is no advice, choose the “cotton” or high-temperature environment; choose “dry” or turn off the steam; unfilled water away from the Iron. Provide the Iron some minutes to hot. Using an iron with at least 1200 watts of power is better.

Step 8

Make the shirt Iron and Put the shirt in the pillowcase. Iron it till it gets flat. Any wrinkles will be visible in the transferred image.

Wash and dry the T-shirt if required

Step 9

Put the paper on the shirt. Using transfer paper for light shirts, put the image face downward. If you use transfer paper for dark shirts, put the print face up and the middle of the image in the center of the T-shirt collar.

Placing the image face downward will permit the image to be transferred. As a result, it does not provide a mirrored image when you transfer it to your shirt.

Step 10

Move with Iron the image over the shirt. Force down the Iron firmly on the cloth for significant pressure. Push downward with your entire hand.

Continue Iron from 30 seconds to some minutes, per the directions that appeared with your particular transfer paper.

Ensure providing heat to every part of the paper, so keep moving the Iron correctly.

Some transfer paper possesses thermal indicators that will alter colors when getting the area is hot enough.

Step 11

Allow the area to get cool. After that, unwrap the paper. Allow it to cool for a few minutes till the paper gets to room temperature.

Unwrap the paper to expose your image below.

Method#2: Transferring an Image with Photo Emulsion Using Screen Printing Method

Step 1

Pick an image one is black another is white. In this black-and-white image, the Black will block out the light. As a result, your design will be allowed to show on the silk screen.

Screen printing method prints black images on the shirt. When you keep a color image to print, change it into Black and white by taking Microsoft Word, Photoshop, or any photo editing device.

Step 2

Keep the image to be printed on a transparency. It is better to use transparent sheets than acetate paper.

Low-quality printers might not print the image excellently, which could print a confusing image on the shirt. If needed, a copy of the transparencies keeps stored.

Some transparency sheets will shrink or warp at the moment of going through the printer. Proceed with a small pack to start so you can run to various brands if the first effort doesn’t work.

Step 3

Take a printing screen and go with a paint of a photo emulsion. These materials are accessible online or at significant craft supplies, frequently a fraction of a single-screen printing kit. Both sides of the screen will (be) Painted with the photo emulsion. Use a squeegee to extend it thin. There will be even layering from corner to corner of the total surface.

You are to wear gloves at the time of handling the photo emulsion.

You also lay a trash bag downward so that you don’t need paint on your table or any other surface.

Wrap an area to some extent more significant than your photo and spread the emulsion evenly. You are not to be able to observe through the screen.

Step 4

Use a dark location to dry the screen. Keep the screen in a dark, cool place for several hours to dry the photo emulsion.

You may set a fan over the screen for a quick drying process.

Step 5:

Arrange a light station. An image is to be burnt through the photo emulsion on your screen when it (is) exposed to light. You need to clear space beneath an intense light source for the screen. You may use direct outdoor sunlight late morning /early afternoon.

By Placing a black garbage bag or cloth under your screen, you can achieve better output. You may use a 150-watt proper bulb.

Step 6:

Make ready the screen and image. Put this up previously to take away the screen from the dark space. Set these matters on top of all others stated in the following-

A big part of cardboard or a big dish

To reduce reflection, takes a piece of black fabric,

Set the screen with the flat part of the screen facing upward.

Make the transparent image face downward and set it close to the screen using tape. A piece of glass,

Step 7

You are to make a depiction of the image at the light station. This step is tactful to obtain correct on your initial attempt as it varies by the intensity of the light. Naturally, the image (is) prepared when the photo emulsion changes to a dull grey-green.

The timing can differ from 2 to 90 minutes, depending on light concentration.

Step 8

Clean the screen. Take away the glass and rapidly carry the screen close to the sink. Put a significant spurt of cold water for quite a few minutes on the recessed surface of the screen. Continue spraying until all wet emulsion has washed away, leaving the image’s outline.

All the emulsion gets washed away for more prolonged light exposure.

When none of the emulsion gets washed away after quite a few minutes, take a photo emulsion remover over the screen and attempt a shorter exposure.

Step 9

Now you are in the stage to print your T-shirts. Your screen becomes a reusable printing device. Practice the following process and transfer the image on your shirt:

Place a piece of cardboard or a barrier inside the shirt to prevent passing from one side to the other.

Insert a small spoonful of screen printing ink on the top of the screen, and drag it crossways with a squeegee to outline a thin coating. Do this quite a few times to make sure an even layer.

Then lift the screen, no moving it against the shirt.

Step 10

Make the shirt heat press, as most printing inks require getting ironed on the shirt with a hot, dry setting. On the other hand, some may only necessitate an hour in sunlight, or you may use a quick run with an ultraviolet drying machine.

It is wise to check your ink label for clear directives previous to the heat set.

When the image has dried, you can wear it.

Method#3: To print Your Shirt with an Ink dye

Step 1

Keep the shirt on a flat shell and make Iron it. For best results, you are to iron your shirt smoothly without any wrinkles.

Ink dye provides better with cotton shirts, so position your Iron with the cotton setting.

Run irons the shirt till all wrinkles have (been) removed, particularly the area you like to print.

Using a dry ironing technique with no steam is wise.

Step 2

Put a portion of foam core/cardboard in your shirt. Make the shirt smooth again.

The cardboard fitting is better as it’s even and cannot allow the ink to pass through to the portion of the shirt. And after doing it, you keep it away.

Step 2:

Make a structure where you desire to put the image. You may take a cardboard or plastic frame.

Make your frame so the ink stays in the printing area. Let’s not tape the image downward.

Step 3

Take a bowl and Pour your Ink dye into it. Make the bottle shake well before pouring the ink.

Your dish must not absorb. It will not be wise for the dye to seep into it.

Do it in a ventilated room so it cannot (be) exposed to substantial natural light.

Step 4

Add the Inkodye to the shirt. Make the brush (be) coated with the dye.

Apply the dye evenly to your preferred region on your shirt. Your shirt should be fresh.

After covering the preferred area, clutch a paper towel and make the area soak up any surplus dye.

Step 5:

Take away the frame to observe the painted region. When you’ve covered the area, you do not require the structure

Step 6:

Print on T‐Shirts by Your T-shirt Screen Printing Machine.

Put your negative over the inked fraction of the shirt. Please press down the negative on your sweater to assist it in attaching to the dyed area.

Make level the area applying your hand. Engage negative to get in touch all over the place with the dye.

Make straight pins over the opposing edges to maintain it in place.

Alternatively, you can place a part of acetate on top of your negative.

Step 7:

Open your print to straight sunlight. Make your shirt attached with the negative on the outside and allow it to soak up the sun so it can dry while transferring the image.

Let print stay in direct sunlight for 10-15 minutes.

Do it around 11:00 am to 3:00 pm when the sun is most active.

Expose your print longer when it gets cloudy out. Examine after five or so minutes to see whether the image darkens.

Step 8:

Take away the negative in a space that isn’t too bright.

Removing the negative at passive lighting can facilitate keeping the print unbroken.

Step 9

Make the shirt in the washing machine as the washing machine is the best choice device to wash. However, you may wash it using just your hands.

A proper wash will remove excess Inkodye from the shirt, and your print will get a nice and fresh look. Warm to hot water can bring a better outcome. Wash it double to take away all the scum.

Now your T-shirt is clean and ready to put on!

Read more:

t-shirt screen printing machine

1. How to Prepare Screens for T-Shirt Screen Printing Machine?

2. Eight Super Guides for T-shirt Screen Printing Machine Users

3. Maxwolf Silk Screen Printing Machine 4 Color 2 Station Double Spring T-shirt Press DIY

Find Here Related Articles on T-Shirt Screen Printing machines:

- How to Prepare Screens for T-Shirt Screen Printing Machine?

- The Best T-shirt Screen Printing Machine|Promo Heat Press Machine

- 6 Simple Steps for Using T-Shirt Screen Printing Machine

- 5 Useful Tips For T-Shirt Screen Printing Machine Users.

- Six Tips to Get the Best T-Shirt Screen Printing Machine

- Ridgeyard 4 Color 1 Station Silk Screen Printing Machine Screen Printing Press T-Shirt Printing Machine

- How to Use Your Screen Printing Machine Properly for T-Shirts?

- Simple Single 1 Color 1 Station T-shirt Silk Screen Printing Machine NS101

- BestEquip Screen Printing Machine for T-shirt DIY Silk Screen Removable Pallet (1 Station 4 Color)

- T-shirt Printing Machine: How Can it Benefit Your Business?

- 9 Best T-Shirt Printing Machines for 2021 | Reviews and Buying Guide

- How to Maintain Your T-Shirt Screen Printing Machine?

- Eight Super Guides for T-shirt Screen Printing Machine Users

Leave a Reply

You must be logged in to post a comment.